Infrastructure

Infrastructure

We are committed to excellence in each Process of textile manufacturing.

At RA Exports, we have carefully installed a holistic infrastructure that caters to the generic as well as specific requirements of the textile industry. Our yarn to finished fabric installation ensures a one-stop solution for wide spectrum of textile products. Our installation reflects our strength and commitment towards quality through our state of art infrastructure.

Spinning

Our Yarn Spinning Mill "RA Mills Private Limited" with 8,400 Spindles where

we produce 100% Cotton Karded Weaving Yarn

from Count's (40's Ne to 60's Ne). Our sister concern "Sri Sowdeswari Mills

Pvt. Ltd." with 16,000 Spindles manufacture 100% Cotton

(Karded & Karded Compact) Yarn from Count's (40's Ne to 60's Ne).

We also have In-house Doubling Machines to produce two-ply yarn depending on

customer needs.

All our yarns are 100% Cotton, Contamination Cleared and Auto-coned as per

International Standards.

Our machinery installations mainly comprise of machines from Lakshmi Machine

Works (LMW), India and Muratec, Japan.

Blowroom, Drawing, Speed Frames and Ring Spinning Frames (LR J9A and LR 6S)

from Lakshmi Machine Works, India and Muratec 21 C Autoconers

from Muratec, Japan. Peass Assembly Winder machines and Jeetsex Ring

Doubling machines to manufacture two-ply yarns.

Dyeing

Our Yarn Dyeing Unit "M/S R. Arthanari Chettiar (Dyeing)" has a

combined machinery capacity to dye upto 3 Tons / Day.

High Temperature High Pressure (HTHP) Vertical Dyeing machines from Dalal

Engineering at various capacities such as

5kgs, 10Kgs, 25Kgs, 50Kgs, 100Kgs, 150Kgs, 200 Kgs, 300Kgs, 500Kgs and 800Kgs

machineries ready at our disposal.

Our Pre and Post Dyeing machineries

include PEASS Package Winder's, Vijay Hydro Extractor's, Room Dryer's and

Textool Cone Winding machines.

Our Zero Discharge Effluent Treatment Plant

with Multi Effect Evaporator (MEE) and Agitated Thin Film Evaporator (ATFD)

helps us to utilize

upto 90% of the treated water back into production.

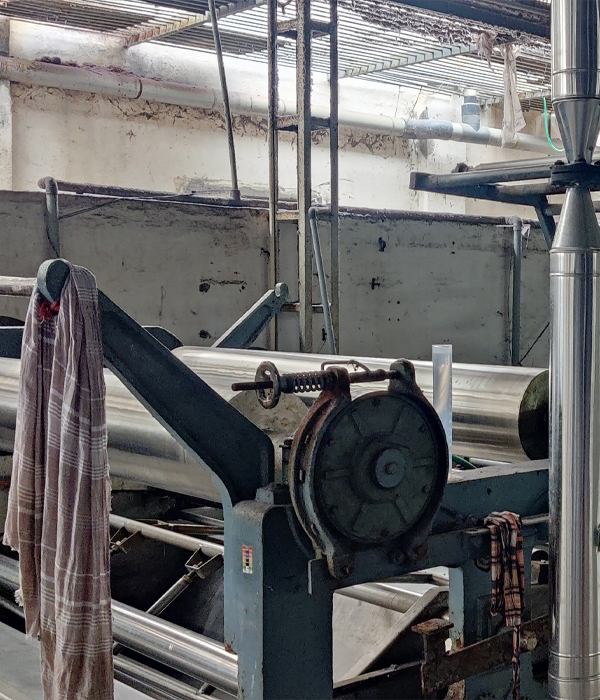

Weaving

Our fabric Weaving Unit comprises of 18 PICANOL Rapier looms

In-house (9 No's - PICANOL GTM-AX and 9 No's - PICANOL GTX).

We also have 100+ Shuttle-less looms for Job-Work like (PICANOL Gamma looms,

SOMET looms and Air-Jet looms) readily available

to meet our production demand.

Our Weaving preparatory line consist of

VAMATEX VM 107 Sectional Warping and Textool Winding machines.

Inspection and Office

We have machineries to execute fabric Sizing, fabric De-Sizing and

Hydro Extraction.

Our next expansion includes the installation of Singeing machine, Fabric Stenter

machine and Sanforizing machine in near future.

Fabric Inspection

machine to

identify even the minute errors in the woven fabric to minimise the fabric

defects before dispatching.

We have highly skilled inspection team to

keenly

monitor the fabric before and after the finishing processes.

Infrastructure

Get in touch

We’re here to help and answer any question you might have. We look forward to hearing from you🙂